Improve Usability and Efficiency Using Membrane Switch for Long-Lasting Results

Improve Usability and Efficiency Using Membrane Switch for Long-Lasting Results

Blog Article

Discover the Versatile Use Membrane Switch in Modern Electronic Devices

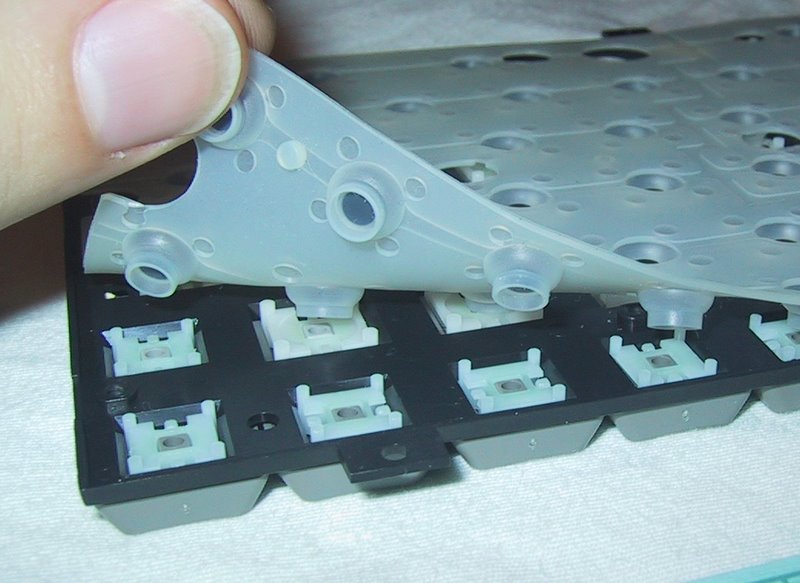

In the world of modern-day electronic devices, the application of membrane layer switches is remarkably substantial, spanning from sleek customer gadgets to vital clinical tools. These slim, flexible interfaces not only simplify gadget operation with their tactile responsiveness yet likewise considerably enhance durability by resisting environmental risks like dampness and dust. As markets continue to evolve, the assimilation of membrane layer switches in devices design is critical, encouraging not just to satisfy but go beyond the extensive demands of both capability and aesthetic allure. Discover a lot more about exactly how these elements are shaping the future of modern technology.

Checking Out the Duty of Membrane Layer Switches Over in Consumer Electronic Devices

Why are membrane layer changes so widespread in customer electronic devices? Membrane buttons are cost-effective to make, making them an eye-catching choice for high-volume production common in consumer electronic devices.

Moreover, these buttons are recognized for their toughness and reduced upkeep. From microwave ovens to remote controls, membrane layer switches give a sensible, user-friendly interface that sustains the vibrant nature of consumer electronic devices.

Membrane Switches in Medical Instruments: Enhancing User User Interfaces

Membrane layer switches additionally play a substantial duty in the world of medical gadgets, where they enhance interface with their distinct advantages. These switches are especially valued for their reliability and simplicity of sanitation, vital in medical care atmospheres where tidiness is paramount. The smooth, sealed surface area of membrane layer switches permits easy sanitation, decreasing the risk of contamination and spread of microorganisms. Furthermore, their design versatility fits the ergonomic and visual demands of clinical devices, making gadgets more intuitive and accessible for healthcare professionals.

Membrane layer buttons likewise add to the toughness of medical devices. Their resistance to liquids and contaminants guarantees that vital equipment continues to be functional in different medical Going Here setups, consisting of surgical treatments where exposure to liquids is typical. This sturdiness, coupled with responsive comments and low-profile layout, makes membrane layer switches an integral part in enhancing the efficiency and safety and security of medical tool user interfaces.

The Impact of Membrane Layer Switches Over on Industrial Devices Design

In the realm of commercial devices design, the consolidation of membrane layer buttons has actually marked a considerable development. The slim profile of membrane layer changes enables for more compact device designs, while their resistance to chemical, water, and dirt impurities makes them excellent for commercial setups.

In addition, the customizability of membrane layer switches over makes it possible for developers to incorporate certain tactile feedback and visual overlays that improve the individual experience and boost performance. This combination sustains operators in achieving accuracy control over intricate equipment. The general impact is a significant improvement in the performance, reliability, and user-friendliness of commercial tools, lining up with the increasing needs for technical improvement and operational performance in contemporary markets.

Conclusion

Membrane switches have transformed modern electronics, supplying streamlined, sturdy, and adjustable user interfaces throughout different sectors. This technology not just meets the requiring conditions of various areas but additionally significantly boosts individual experience, making membrane official site layer switches a foundation of modern electronic layout.

In the realm of modern-day electronics, the application of membrane buttons is remarkably substantial, extending from sleek customer devices to important clinical devices.Why are membrane switches so common in customer electronic devices? Membrane layer buttons are cost-effective to manufacture, making them an eye-catching option for high-volume production regular in customer electronics. From microwave ovens to remote controls, membrane switches offer a functional, straightforward user interface that supports the dynamic nature of consumer electronic devices.

Report this page